Thread rolling

Reliable manufacturing partner

Mechanics of thread rolling

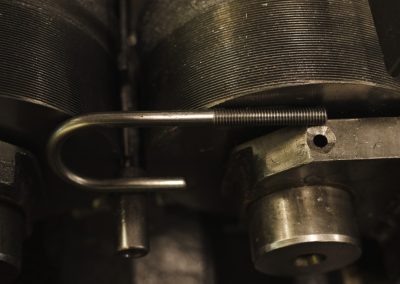

When we talk about thread rolling, we mean a process in which the material is formed under intense pressure. This pressure is generated by specially constructed coils – metal rollers with very high load resistance and a specifically shaped surface, adapted to the specific type of thread you want. This can be imagined, analogous to forming a shape in plasticine by squeezing it firmly in the palm of your hand – in the areas where the pressure is greatest, the material is pressed in, while in other areas it rises, forming thread-like patterns.

Our strengths

Modern machinery

Experienced staff

Short lead time

Quality guarantee

wide range of industries served

Material requirements

In addition to this, it is important that the diameter of the rod is properly selected so that it is smaller than the final diameter of the thread. This is due to the characteristics of plastic machining, where material is not removed, but rather displaced. Therefore, the material that is “pressed” in one place during thread rolling will “flow out” in another, effectively increasing the diameter of the part.

The essence of thread rolling

In practice, thread rolling offers many advantages, both in terms of the quality of the threads produced and production efficiency. However, in order for these benefits to be fully realized, it is important to properly prepare the material and use the right tools and techniques.

Advantages of thread rolling – why is it the preferred machining method?

One of the key steps in the production of screw components is thread forming, and the thread rolling technique clearly stands out from other methods in terms of its many advantages:

Perfection of the detail: One of the overriding strengths of thread rolling is the precision and surface quality of the resulting thread. This treatment does not involve any cuts in the material, thus eliminating the risk of sharp, uneven edges. In addition, the use of a batch bar with the right parameters makes it possible to achieve high process repeatability, which translates into consistency and standardization of the manufactured parts.

Increased strength: Thread rolling not only avoids notching and the potential weakening of the material, but on the contrary, by plastically deforming the bar during the rolling process, its structure is thickened. This effect manifests itself in increased surface strength, making rolled threads more resistant to mechanical damage and corrosion.

Process efficiency and economy: Rolling technology allows for faster thread forming than many traditional machining methods. What’s more, once the rolling process is complete, there is no need for additional processing or removal of material scraps. This not only speeds up the entire production process, but also reduces waste, which is both economically and environmentally beneficial. An additional benefit is the ability to easily automate the rolling process. The mechanism of rotary motion of the rollers allows the rod to be moved in real time, which enables faster material change and increases production efficiency.

Various thread rolling techniques

For mass production, tangential feed rolling and multiple feed rolling are worth noting. In the first technique, two rollers with different diameters and peripheral speeds work together to ensure high rolling efficiency. The second method is a combination of transverse and through-rolling techniques, where the movement of the rollers is synchronized with the workpiece, making it possible to obtain accurate threads of various lengths.

Not to forget specialized methods such as flat-jaw rolling and segmented roller rolling. These techniques are great for specific applications, although tool costs, especially for the latter, can be higher.

The last method, planetary rolling, involves using the planetary motion of the workpiece between two roller segments. It is used in automatic rolling mills, offering high productivity and medium thread accuracy.

The variety of thread rolling techniques allows the process to be precisely tailored to production requirements, taking into account both accuracy and production efficiency. The choice of the right method depends on a number of factors, such as the type of material, the required accuracy or the volume of production.