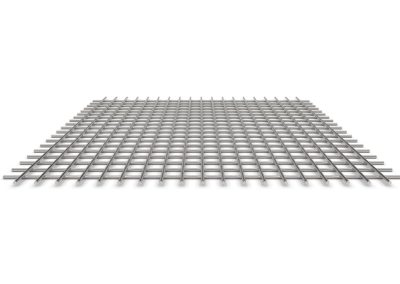

Welded nets

Mesh welding technology

Production of technical nets

Welded nets are used for various purposes, mainly as technical nets. We manufacture them using various steel materials. We weld nets according to customer specifications, our nets are characterized by high strength.

The maximum size of the nets is 3 m long x 1.5 m wide

The production in our company includes welded nets with different mesh spacing, our standard mesh is:

- 20 mm x 20 mm,

- 25 mm x 25 mm,

- 50 mm x 50 mm,

- 75 mm x 50 mm,

- 100 mm x 50 mm,

- 100 mm x 75 mm.

In doing so, the mesh can be square or rectangular. The meshes differ in the thickness of the wire used (from 2 mm to 8 mm) and weight (from 2 kg/m2 to 8.9 kg/m2).

Our strengths

Modern machinery

Experienced staff

Short lead time

Quality guarantee

wide range of production possibilities

What are welded nets made of?

The net itself can be 60 cm, 100 cm, 120 cm or 150 cm high.

The maximum width of the welded mesh sheet will be 2500 mm, and the maximum length – 3000 mm.

We can offer you nets made of steel:

- ordinary,

- galvanized,

- stainless.

The steel wire is joined into a mesh form using a welding technique. The resulting welded nets are extremely durable, so we can guarantee their use for many years.

What is the manufacturing technology of welded mesh?

Application of welded mesh

cover for machinery and equipment

filling balustrades, gates, wickets and fence spans

partitions

breeding cages and pens

filters and strainers

garbage cans and containers

ventilation elements

mesh containers

pallet setters

warehouse racks

Use of welded mesh in many industries

You can also find stainless steel mesh in the food industry and in the chemical industry.

Actually, in our environment we can find numerous examples of the use of welded mesh. The first thing that will surely come to mind for most of you is welded mesh fencing, which until recently was mainly used as technical and industrial fencing. Today they are being used more and more to cordon off private homes and residential neighborhoods.

Grids can be found in high-end modern TV antennas and old-style antennas. They are used to make shopping carts, store shelves and racks, shopping baskets or to create gabions, which are baskets made of mesh that are filled with decorative stones or chipped pieces of rock. Nets are also used to protect the slopes of mountains and make a structure for noise barriers.