Wire bending

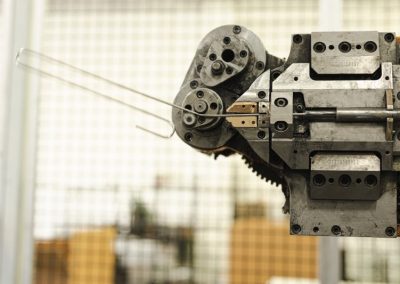

2D and 3D wire bending machines

We also provide additional services for fabricated wire parts such as beveling, welding, pressing, welding and notching.

Wire bending is a specialized field of metalworking, combining precision, technology and years of experience. Robomet has been providing customers with the highest quality products for years, accurately reproducing even the most complex designs.

Our strengths

Modern machinery

Experienced staff

Short lead time

Quality guarantee

Spatial 2D and 3D wire bending

Wide application of wire bending in many industries

Perfect reproduction from CAD spatial design

Types of bending wire and their diameters

Small and large series of wire products

It is not only the size of the project that is important to us. We carry out both one-off, short series of products and permanent productions according to an established schedule. Working with us, you can be sure that even the smallest order will be treated with the same care as large-scale production.

Industries for which we perform wire bending

motorization

industry

furniture making

agriculture

consumer electronics and white goods industry

construction

VIDEO

See how we work

Advantages of wire bending in our company

high-precision manufacturing of elements made of wire of different diameters

The ability to bend wire with different coatings, including PVC

optional threading or automatic welding

Technical details on wire bending

We are able to realize both very simple projects in which the wire is bent in one plane and complex projects, including projects in the space of three dimensions. We also have the ability to weld wire on fully automated equipment, so the range of our capabilities is even significantly increased. We are always happy to check the design sent by the customer and determine the production capacity in this area.

Wire bending machine characteristics and additional services

To meet the expectations of our customers, we also offer additional services such as threading and automatic welding. As a result, products made of bent wire can be enhanced with additional functionality, making them even more versatile and customized.